Houston, USA

LYONDELLBASELL

MEETING STRINGENT LIGHTING REQUIREMENTS WITH LOW GLARE SOLUTION AT LYONDELLBASELL CHANNELVIEW COMPLEX

CU Phosco, in collaboration with FINE EX LAMPS successfully implemented an innovative high mast lighting solution at the LyondellBasell Channelview Complex. This project aimed to provide adequate safety illumination across the vast industrial site while minimising glare for neighbouring areas. Through meticulous planning, cutting-edge technology, and close collaboration, the project achieved its objectives and delivered exceptional results.

LyondellBasell is a global leader dedicated to building a more sustainable future through innovative material solutions and recycling technologies. Thirty miles east of downtown Houston, the Channelview Complex, covering nearly 4,000 acres on the Gulf Coast, is the world's largest Propylene Oxide Tertiary Butyl Alcohol (PO/TBA) plant built on a "greenfield" site in Channelview, Texas, in 2017. The location plays a pivotal role in producing materials critical to modern life.

FINE EX LAMPS specialises in industrial lighting solutions and electrical distribution equipment, partnered with CU Phosco to address this complex's lighting requirements for safety and efficiency.

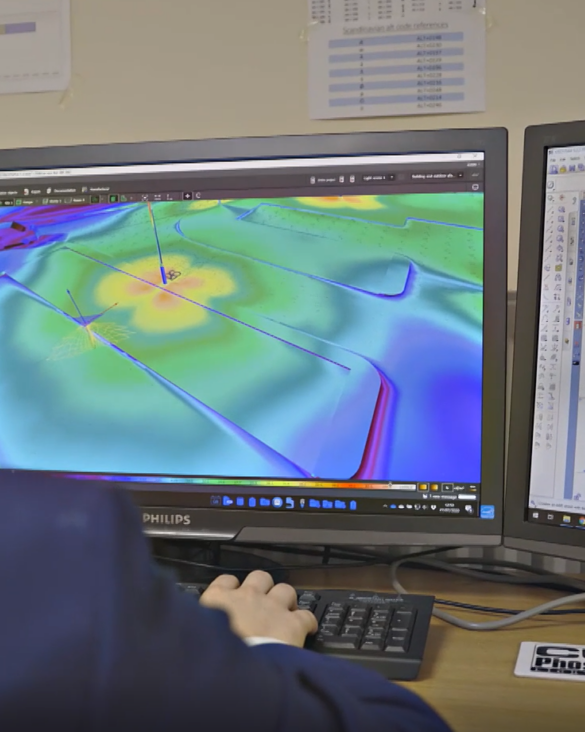

Mitchell Fine, sales engineer, explains, "A lead design engineer at Fluor Enterprises proposed using high mast lighting for this project to meet the high lighting requirements. We provided Lighting Calculations using Lighting Reality software from CU Phosco, which LyondellBasell then approved. We worked closely with CU Phosco to provide drawings of the equipment and received prompt responses from their technical department."

OBJECTIVES

The primary objectives of this project were to ensure minimum light levels (average of 50 lux over the 140-acre site) and visibility uniformity while providing comfort by minimising glare throughout the site and for adjacent industrial areas.

SOLUTION

The collaboration between CU Phosco and FINE EX LAMPS yielded outstanding results. The FL800R LED floodlighting system surpassed expectations by meeting the challenging lighting requirements while offering numerous benefits. The system's exceptional energy efficiency, achieved through high lumen output with minimal lumen depreciation over its life, led to substantial energy and operational cost savings by eliminating wasted light.

Furthermore, the enhanced safety and visual performance across the site met the stringent lighting objectives and contributed to a more secure environment owing to better visibility. The versatility of the system's mounting options allowed for seamless integration into the existing infrastructure, resulting in significant cost savings. This aligns with LyondellBasell's commitment to sustainability, as LED technology reduces energy consumption and carbon emissions.

The durability of the FL800R system, ensured by its AeroFlow® Cooling System and high-quality components, proved effective even in aggressive environments, delivering consistently high performance. The design's focus on minimal glare enhanced safety and promoted a dark sky-friendly environment, reducing light pollution and benefiting both the facility and its surroundings.

Mitchell Fine of FINE EX LAMPS shared his experience: "CU Phosco's high mast lighting solution surpassed our expectations. The FL800R LED floodlighting system not only met the challenging lighting requirements but also demonstrated exceptional energy efficiency and durability. The collaboration between our teams ensured a seamless implementation process, and the client's satisfaction speaks volumes about the quality of the results."

The successful installation of CU Phosco's high mast lighting solution at LyondellBasell's Channelview Complex is an excellent example of the power of collaboration and innovative technology in achieving safety, efficiency, and sustainability objectives. The project met stringent lighting requirements and contributed to energy savings, reduced carbon emissions, and enhanced visual performance across the expansive industrial site.

RESULTS AND BENEFITS

The collaboration between CU Phosco and FINE EX LAMPS yielded outstanding results. The FL800R LED floodlighting system surpassed expectations by meeting the challenging lighting requirements while offering numerous benefits. The system's exceptional energy efficiency, achieved through high lumen output with minimal lumen depreciation over its life, led to substantial energy and operational cost savings by eliminating wasted light.

Furthermore, the enhanced safety and visual performance across the site met the stringent lighting objectives and contributed to a more secure environment owing to better visibility. The versatility of the system's mounting options allowed for seamless integration into the existing infrastructure, resulting in significant cost savings. This aligns with LyondellBasell's commitment to sustainability, as LED technology reduces energy consumption and carbon emissions.

The durability of the FL800R system, ensured by its AeroFlow® Cooling System and high-quality components, proved effective even in aggressive environments, delivering consistently high performance. The design's focus on minimal glare enhanced safety and promoted a dark sky-friendly environment, reducing light pollution and benefiting both the facility and its surroundings.

Mitchell Fine of FINE EX LAMPS shared his experience: "CU Phosco's high mast lighting solution surpassed our expectations. The FL800R LED floodlighting system not only met the challenging lighting requirements but also demonstrated exceptional energy efficiency and durability. The collaboration between our teams ensured a seamless implementation process, and the client's satisfaction speaks volumes about the quality of the results."

The successful installation of CU Phosco's high mast lighting solution at LyondellBasell's Channelview Complex is an excellent example of the power of collaboration and innovative technology in achieving safety, efficiency, and sustainability objectives. The project met stringent lighting requirements and contributed to energy savings, reduced carbon emissions, and enhanced visual performance across the expansive industrial site.